METALLURGY

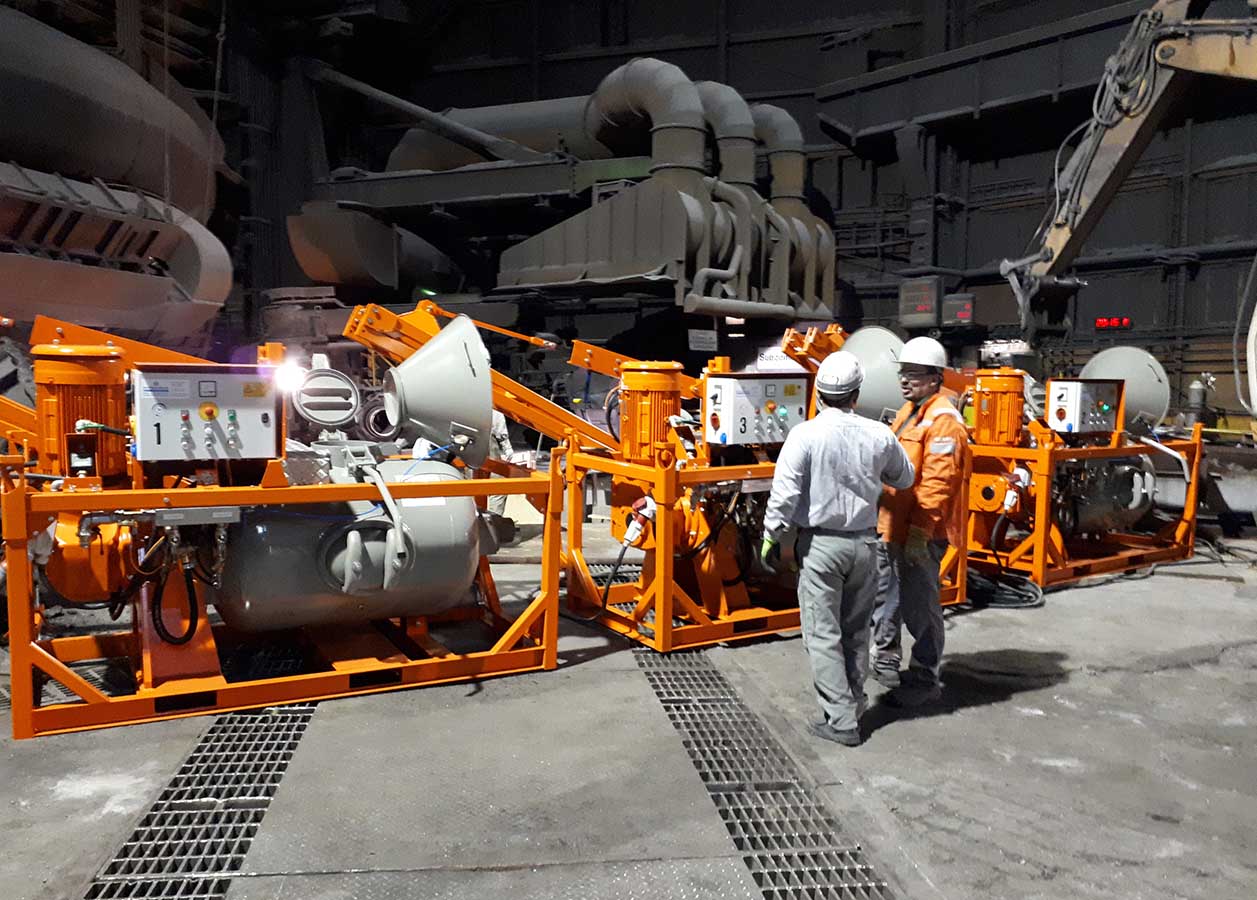

LOEWE offers a full range of services in refractory lining for metal production and processing equipment This includes both the excavating of the worn refractory material, the relining, repair and maintenance of the various plants, as well as the recycling of the different materials.

COKING PLANT

LOEWE is a reliable partner for the refractory services of the coke oven battery. Using ceramic welding, we repair furnace walls and floors in coking plants around the world. We measure the areas which require repairing to achieve the ultimate and lasting effect of maintenance, and we fully document the work in accordance with the quality management guidelines. With our own machines and qualified personnel, we are able to carry out repairs in the shortest possible time. We supply the right material for a variety of applications.

LOEWE also repairs the ceilings of coke ovens.

If you want to eliminate leaks from your battery, we have developed suitable methods to provide you with operational support in achieving this goal.

On request, we offer support in the maintenance of the coke furnace battery.

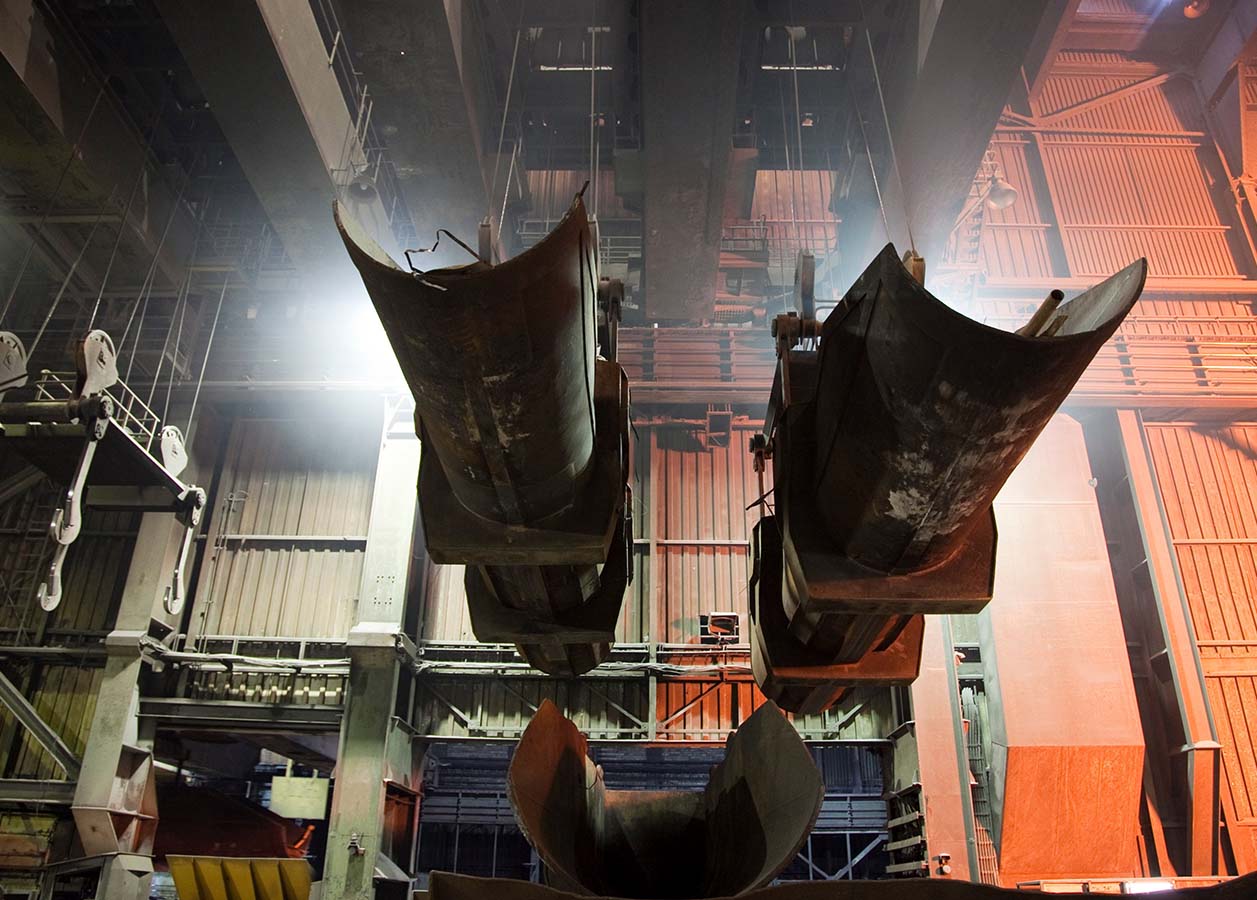

BLAST FURNACE

STEEL PLANT

HEAT TREATMENT FURNACE

For over 5 decades, LOEWE has been a reliable technology partner for the steel processing industry. Each installation of a refractory material requires accurate data on the material properties and energy-saving conditions. LOEWE works in a targeted manner on sustainable lining concepts of walking beam furnaces, rotary hearth furnaces, pusher furnaces, pit furnaces, bogie hearth kiln, annealing hood furnaces and many other furnace types. We provide timely and professional work on the modernization or implementation of new linings for furnace systems.

In this particular field, LOEWE provides customers with all services from a single source, starting with technical planning, through energy consulting, project planning and implementation. We are happy to work with you to develop new refractory solutions.

WE ARE THERE FOR YOU WITH CERTAINTY!

Would you like us to optimize your processes, develop new ideas together or implement sustainable solutions for your company? Then we are the partner you need.

PHONE +49 208 99 47 47 ADDRESS Lessingstraße 4a, 46149 Oberhausen E-MAIL info@loewe-experts.com